|

|

|

|

|

|

|

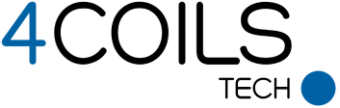

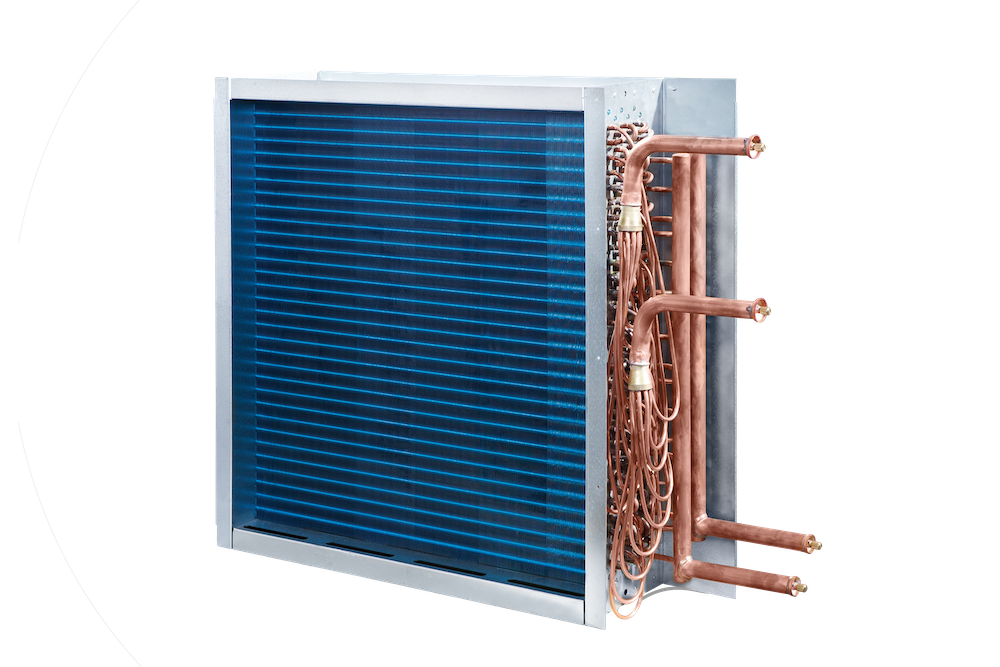

PRODUCED COILS

- special solutions for food, agriculture and industrial segments, data centers or buildings facility

- custom-designed heat transfer coils to original equipment manufacturers (OEM)

- serial and one-piece production coils.

PRODUCT CATEGORIES acc. to PED

SEP (SOUND ENGINEERING PRACTICE)

CAT1 (Module A Assessment): We manufacture in compliance with PED requirements, enabling us to issue a declaration of conformity and affix labels on the product label.

CAT2 (Module A2 Assessment): We collaborate with the notified body TÜV SÜD Czech s.r.o. to produce coils meeting PED requirements, allowing us to provide a conformity assessment and affix marking on the product label, including the notified body mark 1017 under the labels.

LEAK TESTING

Bubble Testing (Compliant with EN 1593):

Our bubble testing method conforms to EN 1593 standards, ensuring reliable leak detection.

Helium testing in accordance with EN ISO 20485, a highly precise method capable of detecting even the smallest leaks, as low as 3g/year, of refrigerants like R22, R134a and other HFL refrigerants

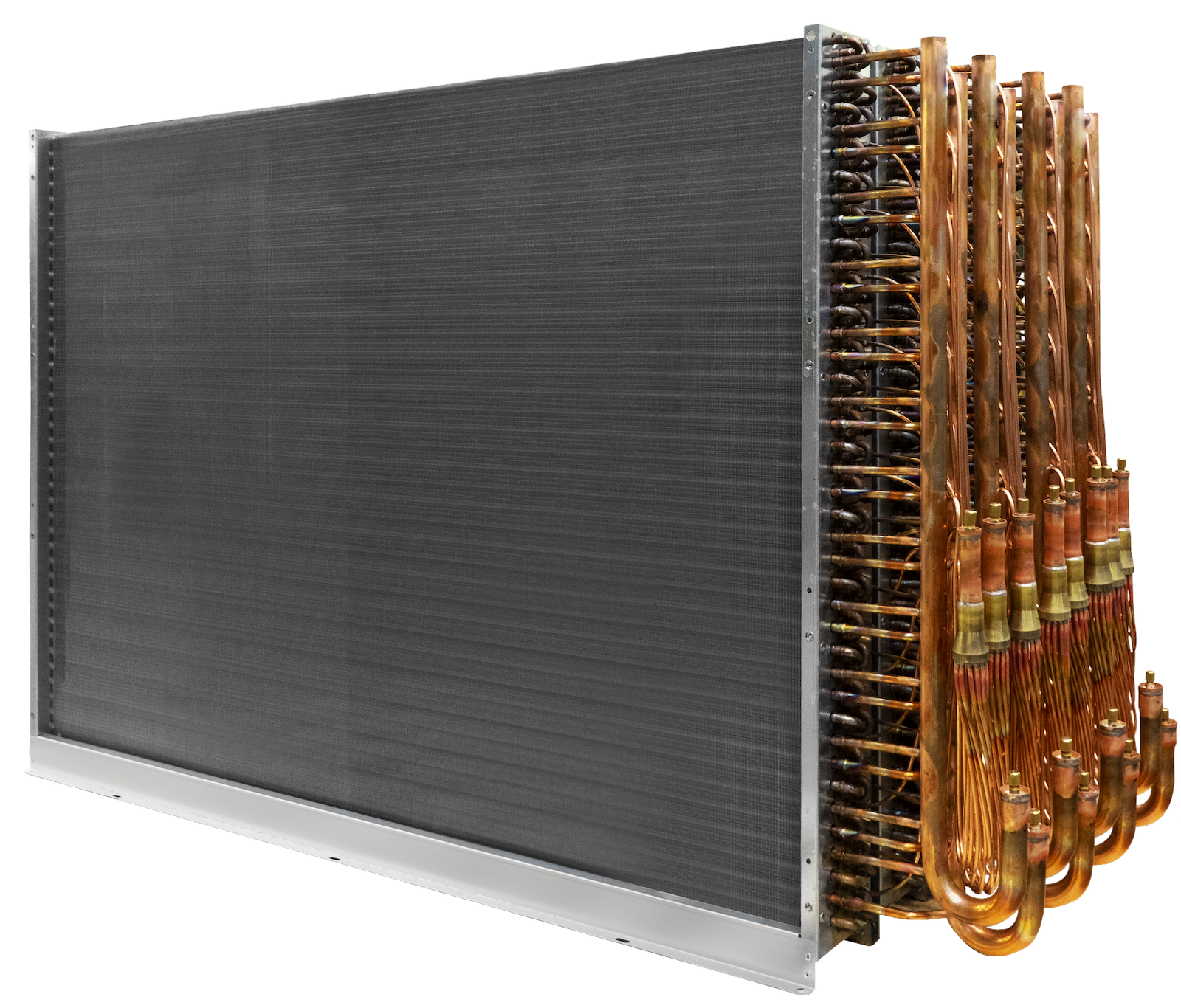

OFFERED SOLUTION

- casing with integrated fan collar for axial fans from ø 260 up to 630 mm

- circuiting for horizontal, vertical or combined use

- straight or bent coils

- usage with high pressure refrigerants R-32 and R410A (tested up to 50 bar)

- some patterns may be produced with defrosting slots/grooves

- powder coat painting in 17 standard colours or according to choice

- the ability to deliver LCE Coating offering anti-corrosion and anti-microbial protection

- possibility to offer evaporators with double fin spacing

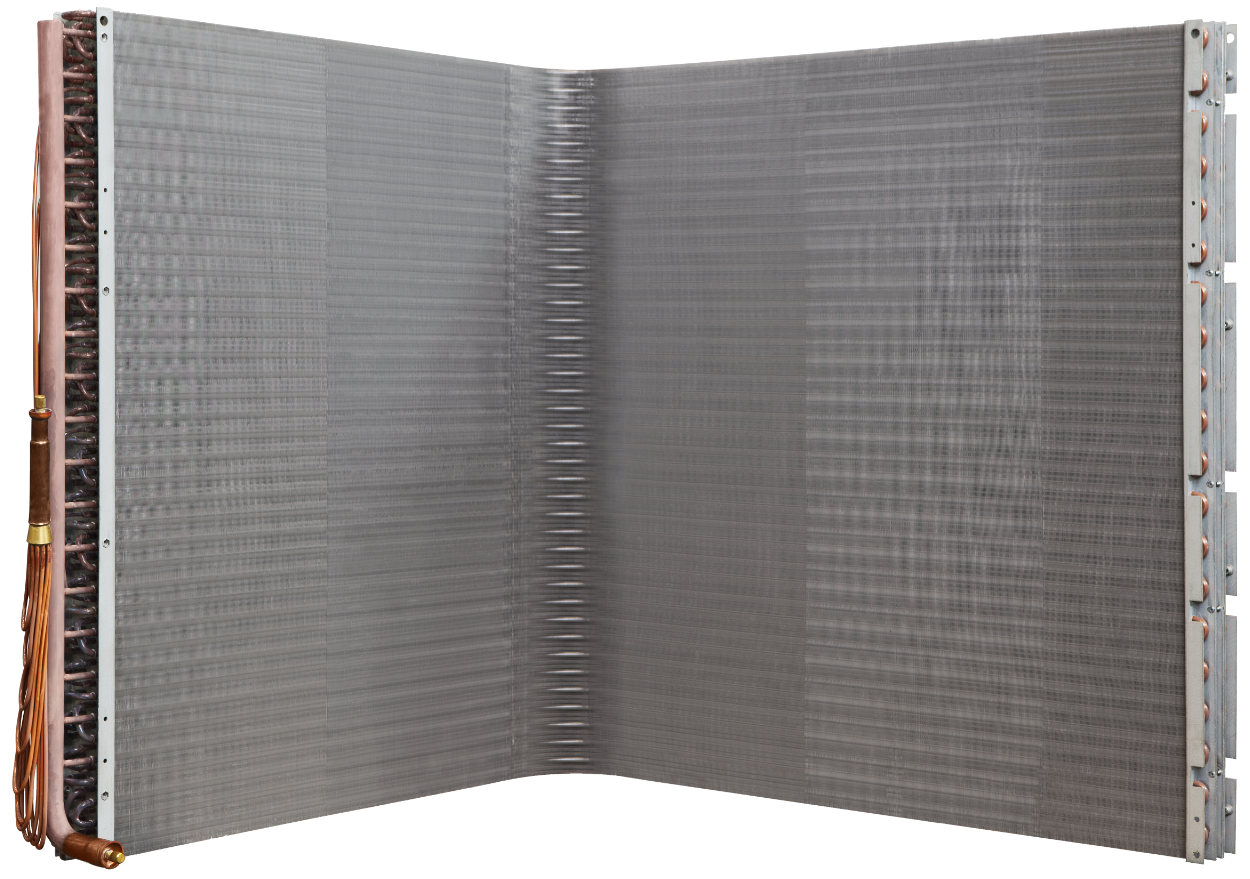

APPLICATIONS

- air handling units

- heat pumps

- transport AC and refrigeration

- cooling boxes and displays

- chillers

- convectors

- rooftops

- condensing units

- milk tanks

- air curtains and unit heaters

- vending machines for food industry and beverages

- free cooling (glycol circuits)

- other applications

|

|

|

|